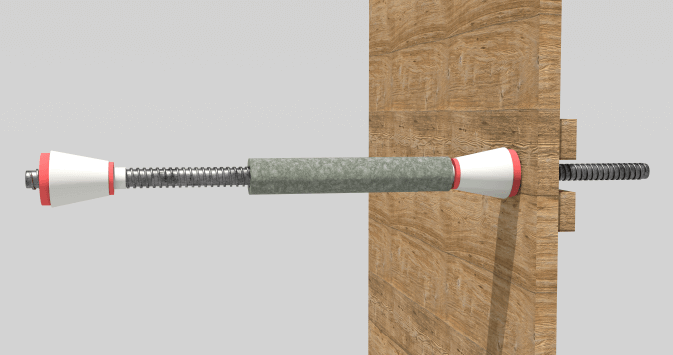

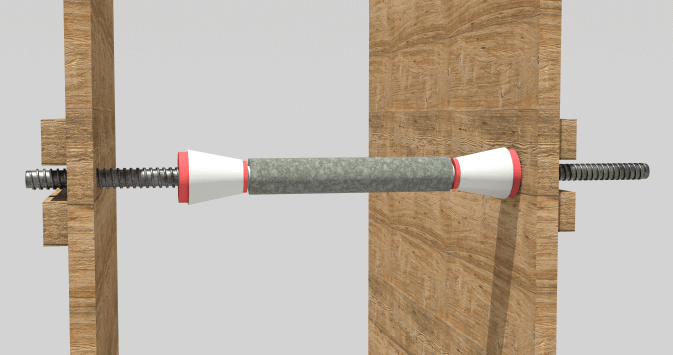

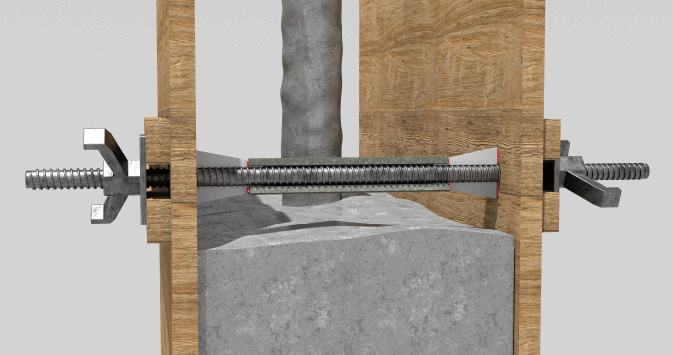

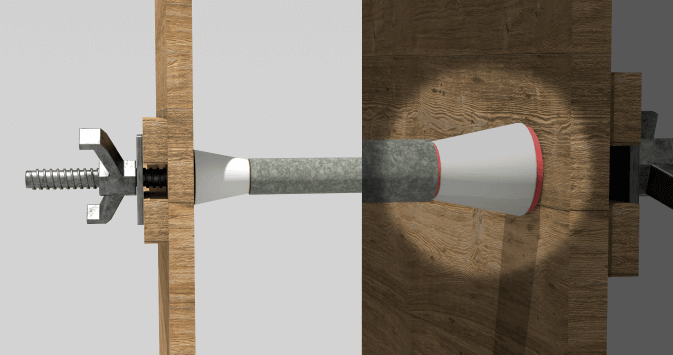

After aligning the formwork and finalizing the reinforcement works, the anchor rod is pushed through a borehole in the formwork near the bolts. Following the threading of the anchor rod, the formwork spacer is pushed over the rod in length of the wall thickness.

The spacer is built like a support cone, an expanding tube made of plastic or fibre cement with another support cone. Subsequently the closing formwork is swung in and aligned. Next is the threading of the anchor rods through the boreholes of the closing formwork. This step takes place from the outside of the formwork panels without insight into the actual form.

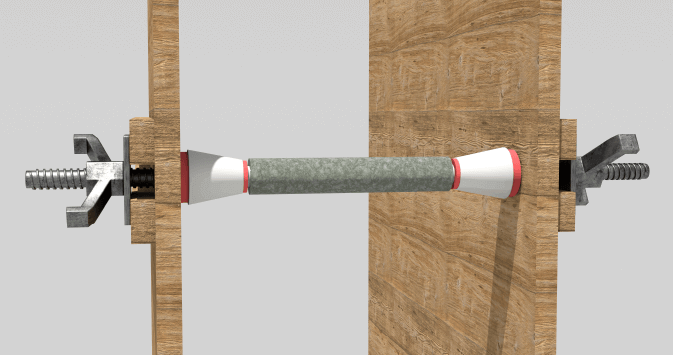

The opposite standing, heavy formwork elements alignment can only be corrected by levering or using a crane. Wing nuts with support plates or combination plates are screwed on from both sides of the formwork. By tightening the clamping points, the formwork is set to the desired wall strength.

If a clamping point system is leaky, water and fine particles of concrete escape. This effect leads to a bleed-out of the clamping point. The consequences range from a circular discoloration around the clamping point to a fraying of the clamping point edge and an exposed grain structure.